Differences in materials of central air conditioning pipe holders (pipe cards, card codes)

Publish Time: 2024-05-06

Comparison and advantages and disadvantages of PE hard holder, wooden holder, polyurethane holder, PEVA rubber and plastic holderAt present, most central air-conditioning pipe supports in the market are still made of wood, which is a kind of central air-conditioning pipe support. It can also be called a pipe card, and some are even called card codes. The main reason is that the materials are different and the names are different. However, The meaning is the same.The main thing is the support code + snap ring, a set of products combined. The clasp is made of iron, but it is divided into stainless steel, cold-rolled steel, hot-rolled steel, galvanized steel, and electrolytic plate materials; there are also many materials for the holding code. This is the main one. The specific analysis is as follows:1. PE Hard Token

Comparison and advantages and disadvantages of PE hard holder, wooden holder, polyurethane holder, PEVA rubber and plastic holderAt present, most central air-conditioning pipe supports in the market are still made of wood, which is a kind of central air-conditioning pipe support. It can also be called a pipe card, and some are even called card codes. The main reason is that the materials are different and the names are different. However, The meaning is the same.The main thing is the support code + snap ring, a set of products combined. The clasp is made of iron, but it is divided into stainless steel, cold-rolled steel, hot-rolled steel, galvanized steel, and electrolytic plate materials; there are also many materials for the holding code. This is the main one. The specific analysis is as follows:1. PE Hard Token

The main ingredients are pressed from various product wastes and leftover materials, mainly PE raw materials. Its advantages are: long service life, very good hardness, and the density can really reach a specific gravity of 450kg/cubic meter. It has excellent load-bearing, but it is expensive.

Disadvantages: No insulation and no shock absorption, which will cause certain damage to the pipeline. It cannot solve the condensation water generated by the central air conditioning pipeline and can only play a role in bearing the load of the pipeline.2. Wooden pallet

Made of wood, it has a short service life, and has shortcomings such as insulating, fireproof, condensation-proof, and non-absorbent. However, the price is the cheapest, but the price is different depending on the wood.3. Polyurethane support code

It is made of isocyanate and polyether as the main raw materials, plus foaming agent, catalyst and flame retardant. It is produced by high-speed stirring and mixing reaction. It must meet the density of 160~500kg/m³ to have low thermal conductivity and low moisture permeability coefficient. Low water absorption and other advantages, but most manufacturers do not achieve this.Disadvantages: no shock absorption, dust generation, short service life (about two to three years), polyurethane brackets produced by general manufacturers do not add flame retardants (so they are not fireproof), and if burned, cyanide poison will be produced, which is not environmentally friendly. Products cannot be diversified and customized for production.4. PEVA rubber and plastic card code (topper)

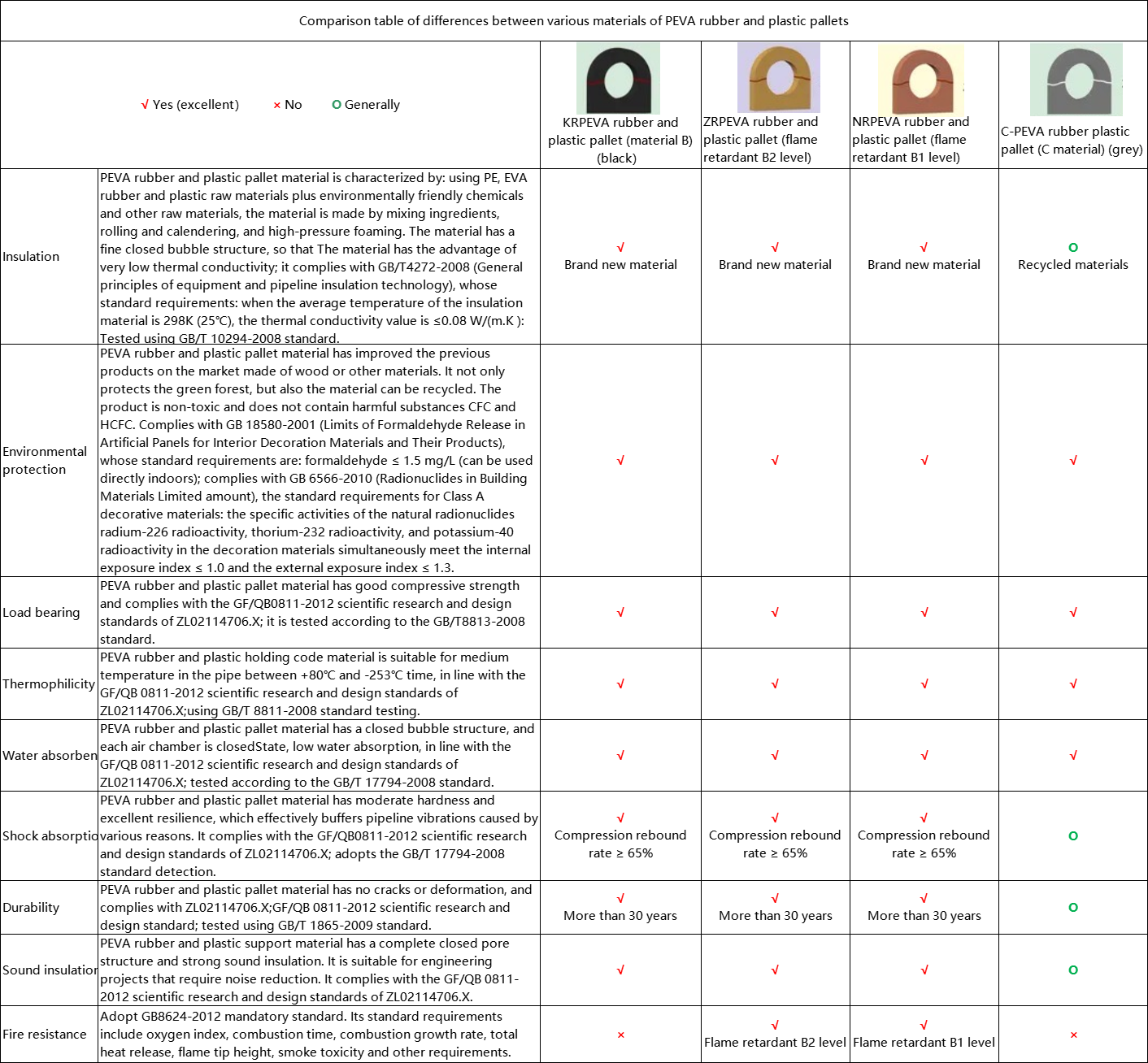

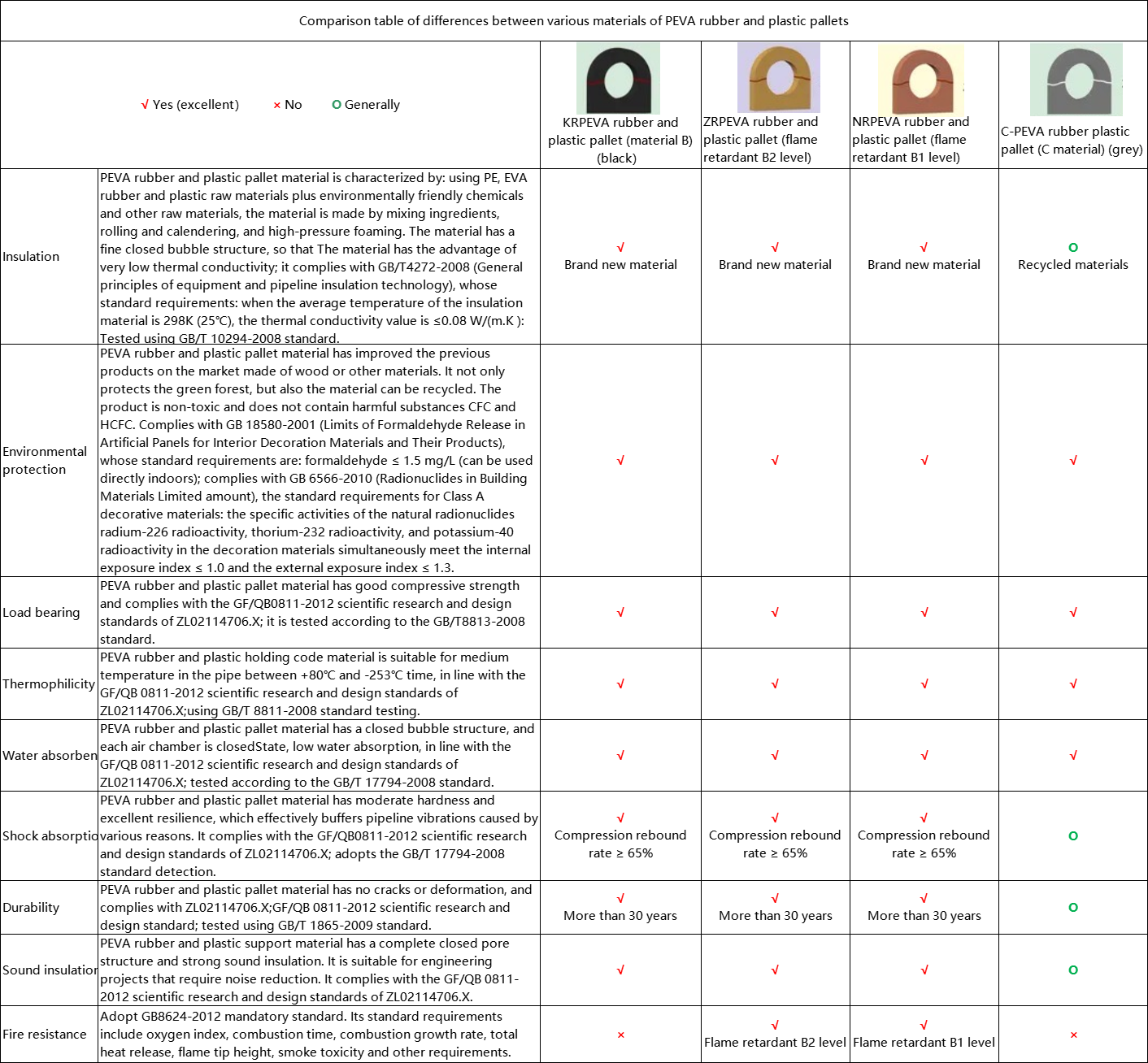

It has similarities with PE hard pallets, but there are also major differences. PEVA rubber and plastic pallets are made of chemical raw materials that are smelted at high temperatures, rolled into sheets, and then foamed at high temperatures. They have a long service life. Very long. If fire-proof raw materials are added to chemical raw materials, they also have fire-proof functions. Therefore, different raw materials have different effects. In addition to fire-proof functions, they also have durability (more than 30 years), thermal insulation (anti-condensation water), shock absorption, Environmentally friendly, low water absorption (almost no water absorption, waterproof), low thermal conductivity, sound insulation, good load-bearing, etc., and can be diversified and customized for production.Disadvantages: 1. The quality requirements are very strict. The density ratio must be above 400kg/cubic meter to ensure the hardness and load-bearing capacity of the board. Most of the products produced by manufacturers have not reached the ratio, so the product hardness is not enough. There are only a few in the country. There are one or two brands that can meet this requirement, such as the "Guofeng" brand. Therefore, the market mistakenly believes that rubber and plastic pallets are not load-bearing. This is because some manufacturers do not control the quality and have an impact on users.2. The quality of different chemical raw materials is different. If the chemical raw materials are made of recycled materials, the products are easy to break, while the products made of new materials are not easy to break. Only the addition of fire-proof raw materials can have fire-proof effect.Summary: Brands are different, manufacturers have different quality control, and the quality and functions of the products they produce are also different. Choosing the material and then the manufacturer’s brand is the best solution. The general price ranking: wooden pallets are the cheapest, and then Recycled rubber and plastic pallet, then PE hard pallet, then new rubber and plastic pallet, then polyurethane pallet (160kg), and finally polyurethane pallet (300kg).